- Room 202, Building 7, No. 125, Yongjun Road, Dalingshan Town, Dongguan City.

What is Vacuum Casting?

Vacuum Casting is a rapid mold replication technology that involves pouring polyurethane (PU) or engineering plastics into a silicone mold under vacuum conditions. The process includes: creating prototypes through 3D printing or CNC machining, making a high-temperature-resistant silicone mold, injecting liquid resin into the vacuum chamber and allowing it to solidify. This technology can precisely replicate the details of the prototype with an accuracy of ±0.2mm, and is suitable for the rapid production of small batches (10-50 pieces) of functional test pieces and appearance samples. It is commonly used in product development stages of industries such as automotive, consumer electronics, and medical.

Advantages of vacuum casting

Can perfectly replicate the details of the prototype (with a tolerance of ±0.15mm), and the surface has a smoothness of Ra1.6μm

Supports over 300 types of engineering plastics such as ABS/PP/PC, including transparent and high-temperature resistant special resins

Single mold can produce 20-50 pieces, with the production cycle shortened by 80% compared to mold opening (delivery time is 3-7 days)

Only 1/10 of the cost of the injection mold is required, suitable for trial production of 50 to 500 pieces.

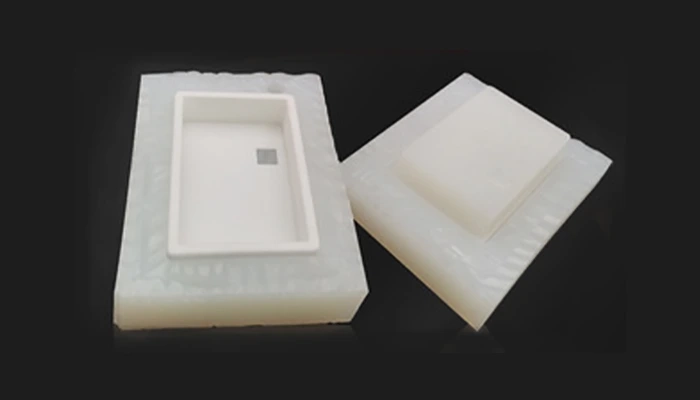

The advantages of silicone rubber mold replication

The mold can be completed within 7 days, with the cost being only 5% - 10% of that of a steel mold.

Capable of replicating fine textures and complex structures with an accuracy of ±0.1mm

Supports 100+ types of engineering plastics such as ABS, PC, and rubber.

Single mode can produce 50 to 300 pieces, suitable for pilot production and verification.

The silicone mold has built-in release properties, ensuring a smooth surface finish.

Choose Qiying silicone rubber mold making service

We focus on rapidly transforming your prototypes into mass-producible replication parts. Through rigorous process control, we ensure that each batch of products maintains dimensional stability within ±0.1mm. We use imported food-grade silicone molds that support 50 to 300 cycles of use, perfectly reproducing complex features including micro-textures as fine as 0.2mm. Our production environment strictly adheres to medical device cleaning standards, providing compliant small-batch solutions for the medical, electronic, automotive, and other industries.

Post-processing of silicone

rubber mold after molding

Demolding and cleaning:

Remove the silicone mold and remove the residual material from the pouring port.

Surface finishing:

Sandblasting (#200 - #400 mesh) or manual polishing to remove parting lines

Stabilization and strengthening:

Heat treatment at 80 - 120℃ for 2 - 4 hours to enhance the material's strength;

Function processing:

Injection/deposition achieves a metallic finish, while UV coating enhances weather resistance.

Post Processing For

Vacuum Casting

Demolding and finishing

After removing the silicone mold, manually remove the parting lines and residual gates Use precision tools to handle the burrs (tolerance controlled within ±0.15mm)

Surface finishing

Grinding with sandpaper in stages (400# → 2000#) Ultrasound cleaning to remove residual mold release agent

Function enhancement

UV coating improves the light transmittance of transparent components Spray painting/ silk-screen printing enables customization of colors and logos

Performance testing

Key dimensions for three-coordinate measurement Weather resistance test (high temperature/humidity cycling)

How to choose between silicone mold re-making and vacuum casting?

Verify the design feasibility (non-load-bearing components)

Very low-cost prototype (< 20 pieces)

The hardness requirement of the material is low (such as a soft

rubber imitation)

Function testing (simulation of the mechanical properties of injection

molded parts)

Highly transparent/highly reflective surface requirements (such as for

prototype vehicle lights)

Complex thin-walled structure (to avoid bubble defects in vacuum)

Classification of mold materials

Wide hardness range (Shore A 30-D 80)

Can simulate the properties of engineering plastics such as ABS, PP, and PC

Supports color matching and transparency adjustment

Shrinkage rate: 0.1% - 0.3%

Mold service life: 15 - 30 times

Available in regular grade / food grade / medical grade

High-temperature resistant resin: Can withstand a continuous temperature of 180℃ (350℃ for a short period), used for components in the engine compartment

Transparent optical resin: Transmittance > 92%, refractive index 1.51, substitutes for PMMAFlexible resin: Shore A 30-60, simulating the touch sensation of rubber

Get In Touch

undefined