ENSURE QUALITY AND DELIVERY TIME

12,000 square meters

of modern production base

300+ senior

engineer teams

300+ advanced

processing equipment

30,000+ satisfied

customers worldwide

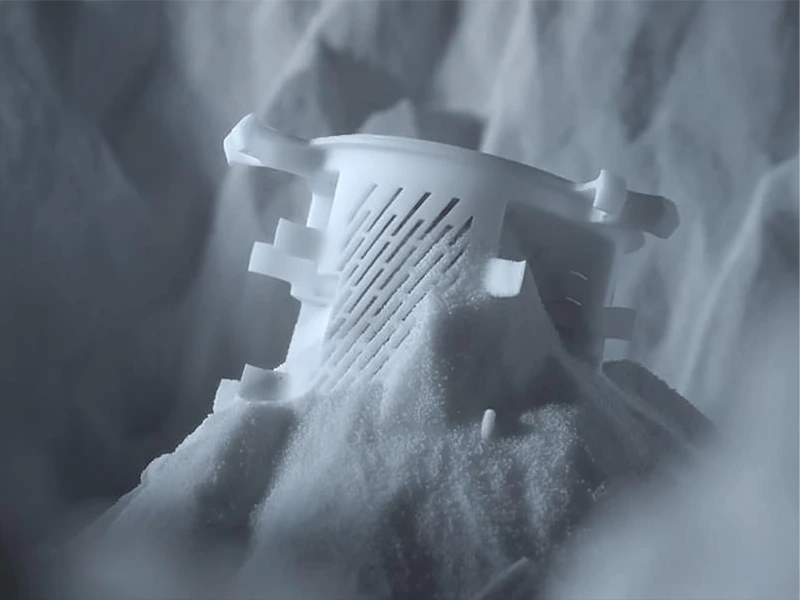

SLS is an industrial-level additive manufacturing process that uses a high-power laser to layer-by-layer fuse nylon, TPU or metal powder materials to directly form complex functional components. Its core advantage lies in:

The un-sintered powder naturally supports the shape, enabling the creation of unconventional designs such as hollow and nested shapes that cannot be achieved through traditional methods.

Nylon (PA12) components have strength comparable to injection-molded parts, and can withstand temperatures up to 180℃.

Capable of printing hundreds of parts at a time, with a cost reduction of 60% compared to CNC.

Qiying uses German EOS industrial-grade equipment, providing one-stop services from design optimization to post-processing, helping the automotive, medical, and industrial fields achieve lightweight and rapid manufacturing.

No supporting structure required, freely realizing complex cavities and movable components;

Industrial-grade nylon (PA12/PA11) and TPU materials, with mechanical properties comparable to injection molded parts;

Can produce hundreds of parts in a single batch, efficiency increased by 5 times compared to traditional processes;

High temperature resistant (180℃), resistant to chemical corrosion, directly used in end products

Chemically resistant, food-grade safe, low density, lightweight

To start, simply select a manufacturing process and upload a 3D CAD file.

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Our digital manufacturing process allows us to produce parts in as fast as 1 day.