- Room 202, Building 7, No. 125, Yongjun Road, Dalingshan Town, Dongguan City.

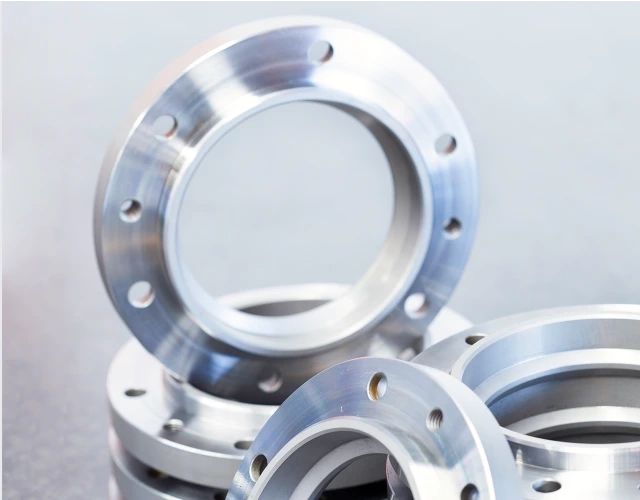

What is CNC machining?

CNC machining (Computer Numerical Control machining) is an advanced manufacturing process that controls precision machine tools through digital programs to shape materials such as metals and plastics by cutting. It employs methods like milling, turning, and drilling to achieve an ultra-high precision of ±0.01mm and is adept at producing complex geometric structures and high-load functional parts. Combining batch efficiency with prototype flexibility, it is the preferred processing technology for core components in fields such as aerospace, automotive, and medical.

Why choose Qiying

Qiying - Your ideal partner for CNC machining

Quality · Value · Service - A Tripartite Commitment to Excellence

At Qiying, we consistently deliver reliable quality, competitive prices and industry-leading customer service, making us your preferred choice for CNC milling solutions. No matter the size or complexity of the project, our advanced equipment configuration can handle it perfectly.

No minimum order quantity

from a single prototype to mass production, flexible response

Quick delivery

shorten your product development cycle

Full-process support

from design optimization to final delivery, one-stop service

CNC MACHINING APPLICATIONS

There are many ways that CNC Machining can be appalled in the commercial and domestic space. Some of the notable applications include the following.

This is the use of an insert to make a specific shape of an object by injecting molten material into it while it’s still hot. Once it solidifies, it leaves behind the final product. Injection molding is used in making automotive parts, storage containers, furniture, mechanical parts for machines, among many other things.

Prototyping is the process where experimental models are made to address a certain problem. Usually, this prototype CNC machining requires a lot of time, but thanks to advanced technologies and machines, rapid prototyping is now possible. The process can be applied in creating car parts and home appliance components in huge numbers.

Appearances are everything, and CNC machining can be used to convert a flat-looking surface into a beautiful finish. This comes in handy when dealing with automobiles, home appliances, among many other daily use products.

Typical materials for CNC machining of metals

Aluminum alloy

Typical grades: 6061, 7075, 5052

Characteristics: Lightweight, easy to machine, corrosion-resistant

Applications: Aerospace structural components, electronic enclosures,

automotive parts

Stainless Steel

Typical grades: 304, 316, 17-4PH

Characteristics: Corrosion-resistant, high strength, but with significant

work hardening

Applications: Medical devices, chemical equipment, food machinery

Carbon Steel / Alloy Steel

Typical grades: Q235, 45#, 4140

Characteristics: Low cost, high strength, requires rust prevention treatment

Applications: Gears, shafts, mold bases

Copper Alloys

Typical grades: Brass (H62), Copper (T2), Beryllium Copper

Characteristics: Excellent electrical and thermal conductivity, tendency

to stick to tools

Applications: Electrodes, heat sinks, electronic connectors

Titanium Alloy

Typical grades: Ti6Al4V (Grade 5), CP titanium

Characteristics: High strength ratio, biocompatibility, but rapid tool wear

Applications: Components for aircraft engines, orthopedic implants

Core Advantages of CNC Machining

The positioning accuracy reaches ±0.005mm, and the surface roughness is within Ra0.8μm Five-axis linkage can achieve an angle precision of 0.01° (such as in the processing of impeller blades)

Supports features such as deep cavities, micro-holes (minimum Ø0.1mm), and irregular curved surfaces. The car milling combined process enables "the completion of all processes in one setup"

Metal: Aluminum alloy/Titanium alloy/Hot-rolled nickel-based alloy (hardness ≤ 60HRC) Non-metal: Engineering plastics/Composite materials/Ceramics (Special tools are required)

CV value (dimensional variation coefficient) < 0.5% The automated production line can achieve 24-hour continuous processing.

CAD/CAM seamlessly integrated, rapid model change (within 30 minutes) Internet of Things (IoT) for real-time monitoring of tool wear, temperature and vibration

Our CNC machining capabilities

Our CNC machining services

At Qiying, we're experts in CNC machining production and prototyping, ready to meet your specific needs. Whether you're after precision for smaller quantities or large-scale production, our services are tailored just for you.

3, 4 & 5 Axis CNC Milling

Multi-axis 3 & 5 axis CNC machining from our global supply chain provides one-off prototypes to large-scale production, ensuring consistent quality and lead times.

CNC Turning

CNC Turning from our global supply chain offers one-off CNC prototypes to large-scale production.

Get In Touch

undefined