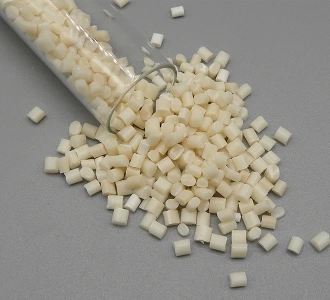

PLA

PLA (Polylactic Acid) is a bio-based, biodegradable thermoplastic polyester widely used in 3D printing, packaging, medical fields, and more.

Eco-friendly and easy to print,Moderate strength

FDM

Educational models, creative prototypes

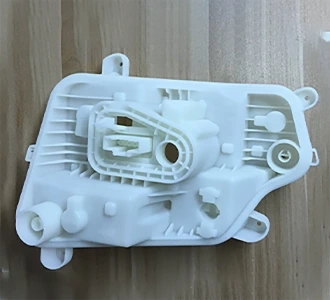

ABS

ABS (Acrylonitrile Butadiene Styrene) is a commonlyused thermoplastic engineering plastic, with its characteristics derived from the synergistic effects of its three monomers.

Impact-resistant, polishable with acetone

FDM/SLS

Functional components, automotive interiors

RESIN

Resin refers to a category of synthetic or natural high-molecular-weight compounds that transition from a liquid to a solid state through a curing reaction. In industry, it typically denotes engineering resins (such as epoxy resin, polyurethane resin) or 3D printing photopolymer resins.

Eco-friendly and easy to print,Moderate strength

FDM

Educational models, creative prototypes

NYLON

Nylon is a synthetic polymer belonging to the polyamide (PA) family, known for its high strength, toughness, and chemical resistance.

High strength, wear resistance, design freedom

SLS/MJF

Industrial parts, aerospace, medical, consumer goods, etc.

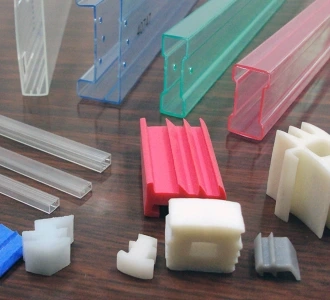

PETG

PETG (Polyethylene Terephthalate Glycol-modified) is a commonly used 3D printing material that combines the ease of printing of PLA with the toughness of ABS, while offering superior chemical resistance, impact resistance, and transparency.

High impact resistance (better than PLA), moderate rigidity,and good wear resistance. Semi-transparent, with improved light transmission achievable by increasing layer height and printing at slower speeds.

FDM

Functional prototypes, packaging design, medical devices, etc.

TPU

TPU (Thermoplastic Polyurethane) is a block copolymer composed of soft segments (polyether or polyester) and hard segments (diisocyanate and chain extenders).

High elasticity, tear resistance, and wear resistance. Resistant to oil, solvents, and hydrolysis. Some TPUs are biodegradable or recyclable.

SLS/FDM

Flexible components, industrial parts, consumer goods, etc.

ASA

ASA Material (Acrylonitrile-Styrene-Acrylate Copolymer) is a weather-resistant engineering plastic commonly used for outdoor 3D printed products (such as automotive parts, outdoor decorations, etc.).

UV-resistant, moisture- and heat-resistant, maintains color stability without yellowing or embrittlement during long-term outdoor use. Resistant to weak acids, alkalis, greases, and alcohols. Can be sanded and painted, easily achieving a smooth surface.

FDM

Outdoor functional components, architectural and landscape models, industrial prototypes, etc.

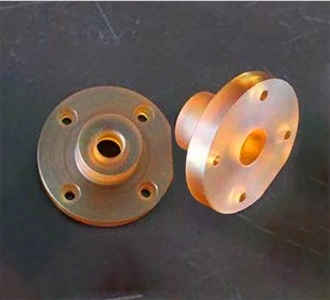

PEI

PEI (Polyetherimide) is a high-performance thermoplastic engineering plastic known for its excellent high-temperature resistance, mechanical strength, chemical stability, and flame retardancy. Its glass transition temperature (Tg) is approximately 217°C, with a long-term service temperature of up to 170°C or higher, making it suitable for high-temperature applications.

High-temperature stability and dimensional stability Strong interlayer adhesion: Minimizes cracking risks during FDM printing due to excellent layer bonding.

Surface smoothness: Can be improved through polishing or vapor smoothing.

FDM

Aerospace, automotive, electrical & electronics, medical, and industrial molding.