ENSURE QUALITY AND DELIVERY TIME

12,000 square meters

of modern production base

300+ senior

engineer teams

300+ advanced

processing equipment

30,000+ satisfied

customers worldwide

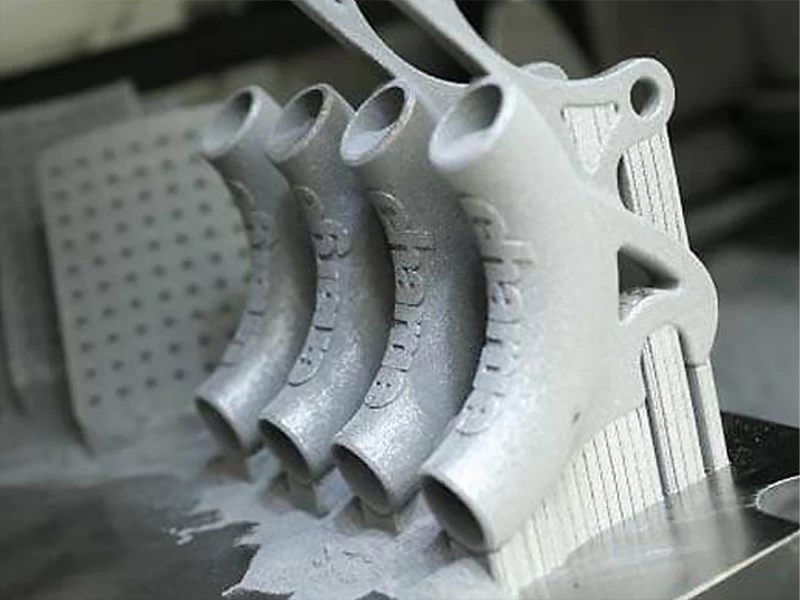

DMLS is an industrial-grade metal additive manufacturing process that uses a high-power laser (200-400W) to melt metal powder layer by layer (with a layer thickness of 20-60μm), directly forming complex metal parts.

We are equipped with industrial-grade high-precision large-scale 3D printing equipment,

which enables us to quickly meet the production demands for various complex parts.

Regardless of the size or application field of your project, we can offer

competitive prices and high-quality products. We can provide a quotation within

24 hours and deliver the goods within the shortest 3 days, helping you accelerate the product development process.

Material Diversity

Supports 50+ metals including stainless steel (316L), titanium alloy (Ti6Al4V), and aluminum alloy (AlSi10Mg), achieving ≥99.5% density with forged-part mechanical properties.

Integrated Complex Structures

Enables geometries impossible for conventional processes:

1.Conformal cooling channels (mold industry)

2.Topology-optimized lightweight structures (aerospace)

3.Porous biomedical implants

Precision Manufacturing

Tolerance: ±0.05mm | Surface roughness: Ra 6-12μm | Minimum feature size: 0.3mm

Qiying adopts a full-process digital control system to ensure that every step from the document to the final product complies with the ISO 9001 quality standards, providing customers with high-precision and highly consistent SLA printing services. A Comprehensive Analysis of the Entire Process of SLA Light-Curing 3D Printing:

Features: Corrosion-resistant, biocompatible, medium strength

To start, simply select a manufacturing process and upload a 3D CAD file.

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Our digital manufacturing process allows us to produce parts in as fast as 1 day.