ENSURE QUALITY AND DELIVERY TIME

12,000 square meters

of modern production base

300+ senior

engineer teams

300+ advanced

processing equipment

30,000+ satisfied

customers worldwide

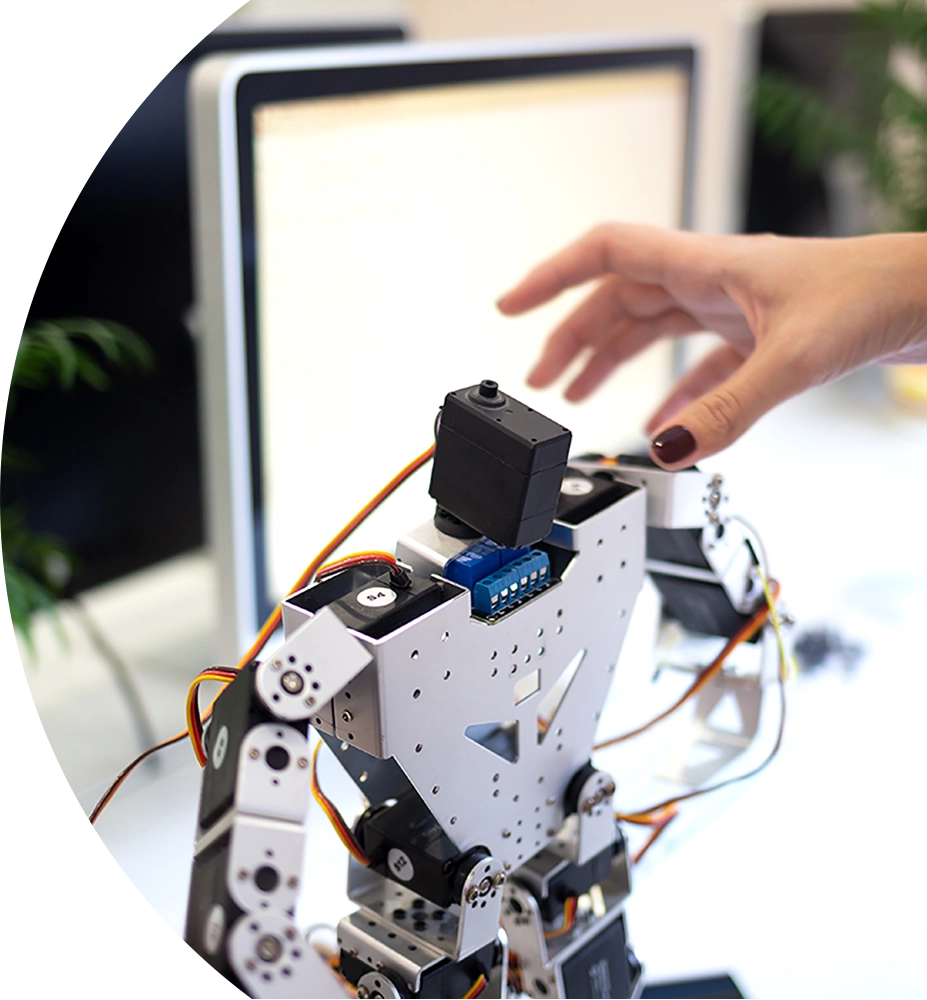

At Qiying, we provide robotics and automation customers with rapid prototyping and services like CNC machining and Injection Molding. Our expert team has the knowledge and skills to help bring new product concepts to life. For more information on our prototyping capabilities and how we serve the robotics industry, contact us or request a quote today.

Qiying has many years of experience in prototyping and manufacturing parts for robotic applications. We use rapid prototyping and digital manufacturing technologies to produce high-performance prototypes and parts that can be seamlessly integrated into complex robotic systems.

Strong production capabilities

We can complete orders of almost any size, from one-off prototypes to mass production.

Range of Services

As a parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Ultra-high precision

Our precision machining can achieve tolerances as low as +/- 0.005 mm, suitable for micro and nano robotic systems.

Fast delivery cycle

With an extensive network of facilities and partners, we can quickly complete orders regardless of quantity or complexity.

Through our manufacturing partner network, we provide access to strong, lightweight materials and surface finishes that can weather every application.

Choose from more than 30 metal alloys and hundreds of industrial-grade plastics.

Steel & stainless steel: 303, 316/316L, 15-5, Tool Steels, 4140, 1.7225

Aluminum: 6061-T6, 6082, 7075-T6, 5083-H111, 2017

Brass & Copper Alloys: C360, Copper C110, Copper C101

Inconel: Inconel 718

Improve durability and performance with a selection of finishes

Anodizing/Electroless nickel plating

Black oxide/Chromate conversion coating

Powder coating/Passivization

Insert installation/Heat treatment

The robotics and automation industry requires a wide range of parts made from both metals and plastics. Typical priorities for robotics customers include:

Tight tolerances for critical parts and complex assemblies; Low-friction parts that can perform repetitive movements; Excellent quality control via on-machine inspection and/or CMM