ENSURE QUALITY AND DELIVERY TIME

12,000 square meters

of modern production base

300+ senior

engineer teams

300+ advanced

processing equipment

30,000+ satisfied

customers worldwide

Our online 3D printing service enables you to 3D print your custom part on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With more than 120 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

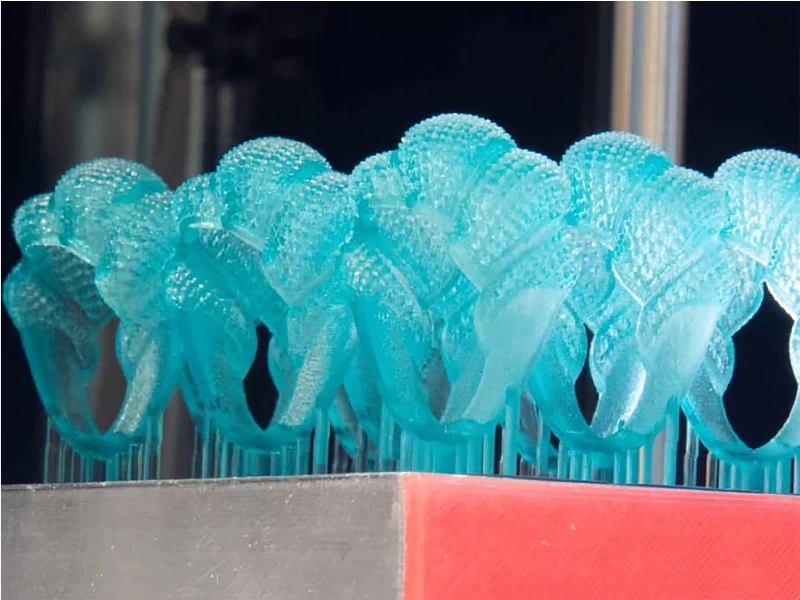

Stereolithography (SLA)

SLA (Stereolithography) offers unrivalled feature detail and surface quality. Ideal for visual prototypes and models as well as moulds and form and fit checks. Offering ABS-like, PC-like and Silicone in many colours.

Selective Laser Sintering (SLS)

SLS 3D Printing is popular for inexpensive industrial applications. Offers high performance Nylon materials PA11, PA12, PP and flexible TPU. It also offers glass filled options for further mechanical performance.

HP Multi-Jet Fusion (MJF)

HP MJF 3D Printing service offers high performance Nylon materials PA11, PA12, and flexible TPU-95A and Ultrasint TPU offering consistent mechanical performance.

Direct metal laser sintering (DMLS)

Direct metal laser sintering (DMLS) is best for parts with complex geometry requiring production-grade materials such as Stainless Steel 316L, Aluminium AlSi10Mg, Inconel 718 and Titanium Ti6AI4V.

Fused Deposition Modelling (FDM)

FDM 3D printing offers low cost and fast turnaround functional parts for prototyping, durable manufacturing tools and jigs. A range of rigid plastics including ABS, PC and ULTEM are available.

3D printing technology, with its advantages of rapid prototyping, high design flexibility and low-cost customization, has been widely applied in various fields. In industrial manufacturing, it is used for rapid prototype development, functional test pieces and small-batch production; in the medical field, it is used to customize surgical guides, bionic prostheses and dental models; in the consumer electronics industry, it is used to iterate product shell designs.

Moreover, in aerospace, automotive parts, architectural models, educational teaching aids and cultural and creative products, 3D printing can achieve complex structures that are difficult to be accomplished by traditional techniques, significantly shortening the research and development cycle and reducing production costs. With the innovation of materials and improvement of precision, its application scenarios are still continuously expanding.

3D printing technology offers an efficient and flexible solution for product prototype development, capable of quickly transforming design concepts into physical models. Through processes such as FDM, SLA or SLS, high-precision prototypes can be produced within 24 to 72 hours, significantly shortening the R&D cycle. 3D printing supports the one-step formation of complex geometries without the need for traditional molds, making it particularly suitable for structural verification, assembly testing, and appearance evaluation.

Using materials such as PLA, ABS or photosensitive resin, prototypes can be both functional and cost-effective. Engineers can identify and correct design issues at an early stage, reducing the cost of later modifications. This technology has been widely applied in industries such as consumer electronics, automotive, and medical, helping customers accelerate the product launch process and is an indispensable tool for innovative R&D.

Applications: Lightweight structural components, engine fuel nozzles, satellite brackets

Applications: Surgical planning, implants, dentistry

Applications: Prototype verification, end components, customized tools

Applications: Shell iteration, heat dissipation structure, flexible components

Applications: Complex fixtures, spare parts repair, fluid devices

Applications: Building models, functional components, construction tools

Applications: Oil and gas equipment, wind power components, hydrogen energy

Applications: Teaching models, experimental apparatuses

Our online 3D printing service enables you to 3D print your custom part on demand. We offer six 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With more than 120 3D printers, we have unmatched capacity that reliably delivers parts within days. In addition to a broad material selection, we offer several post-processing options to improve cosmetics or enhance mechanical properties.

At Advanced Plastiform, Inc., we take pride in manufacturing high-quality, durable custom plastics to our clients across a variety of industries, including automobile, construction, and material handling. In addition to using innovative technology and equipment plus having a team of experienced designers, engineers, and manufacturers on hand, we also work with multiple types of thermoplastic materials. This allows us to use the right material for the product to get the best results. One of the most common plastics we use is acrylonitrile butadiene styrene, often called ABS.

To start, simply select a manufacturing process and upload a 3D CAD file.

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Our digital manufacturing process allows us to produce parts in as fast as 1 day.