ABS-LIKE MATERIAL

ABS-Like material is a type of imitation ABS resin commonly used in rapid prototyping (e.g., 3D printing) and molding processes (e.g., silicone casting). Its properties are similar to those of traditional injection-molded ABS plastic but are produced through light-curing or casting techniques.

Smooth surface with excellent detail reproduction.

Better impact resistance and flexibility compared to standard resins.

Can be further refined through post-processing (e.g., sanding, painting).

Small-batch prototype production,Product validation,Short-run manufacturing,Multi-material simulation

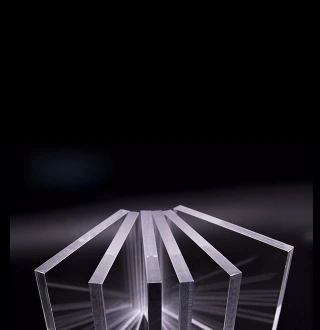

ACRYLIC-LIKE MATERIALS

Acrylic-like materials refer to substances that exhibit properties similar to acrylic resin (PMMA),

High transparency (comparable to PMMA)

Excellent surface gloss

Superior weather resistance

Moderate mechanical strength

Easy to process and mold

Rapid prototyping,Small-batch production,Transparent component replication,Optical component prototyping, Decorative parts manufacturing

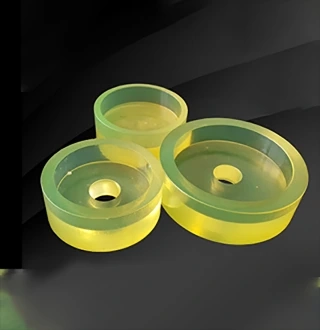

OPAQUE ELASTOMER

Opaque Elastomer is a high-molecular-weight material with rubber-like elasticity, typically in an opaque (non-transparent) state. It exhibits properties such as flexibility, wear resistance, and chemical corrosion resistance.

High Elasticity & Flexibility: Offers rubber-like stretch and rebound properties, making it suitable for deformable components.

Chemical Resistance: Resists common solvents, oils, and weak acids/alkalis.

Wear Resistance: Durable surface withstands friction, ideal for frequently used parts.

Opaque Appearance: Conceals the original mold color or internal structures, suitable for applications requiring visual obscuration.

Dimensional Stability: Low shrinkage after curing, ensuring precise detail replication.

Adjustable Hardness: Hardness can be modified (e.g., Shore A 10-90) through formulation adjustments.

Prototype replication, small-batch production, functional testing, art & design.

WATERCLEAR ELASTOMER

Waterclear Elastomer is a transparent, highly elastic silicone or polyurethane-based material commonly used for mold-making (replica molding) applications.

Optically clear: Capable of replicating fine details, even for optical components.

High elasticity: Facilitates easy demolding, making it suitable for complex geometries.

Low viscosity: Ensures easy pouring and minimizes bubble formation.

Prototyping, mold-making, medical and biological models, electronic encapsulation.