ENSURE QUALITY AND DELIVERY TIME

12,000 square meters

of modern production base

300+ senior

engineer teams

300+ advanced

processing equipment

30,000+ satisfied

customers worldwide

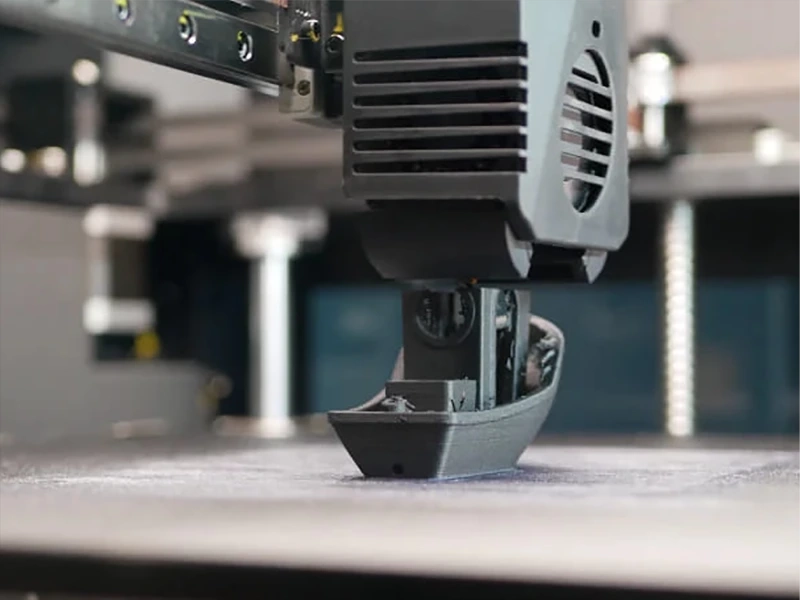

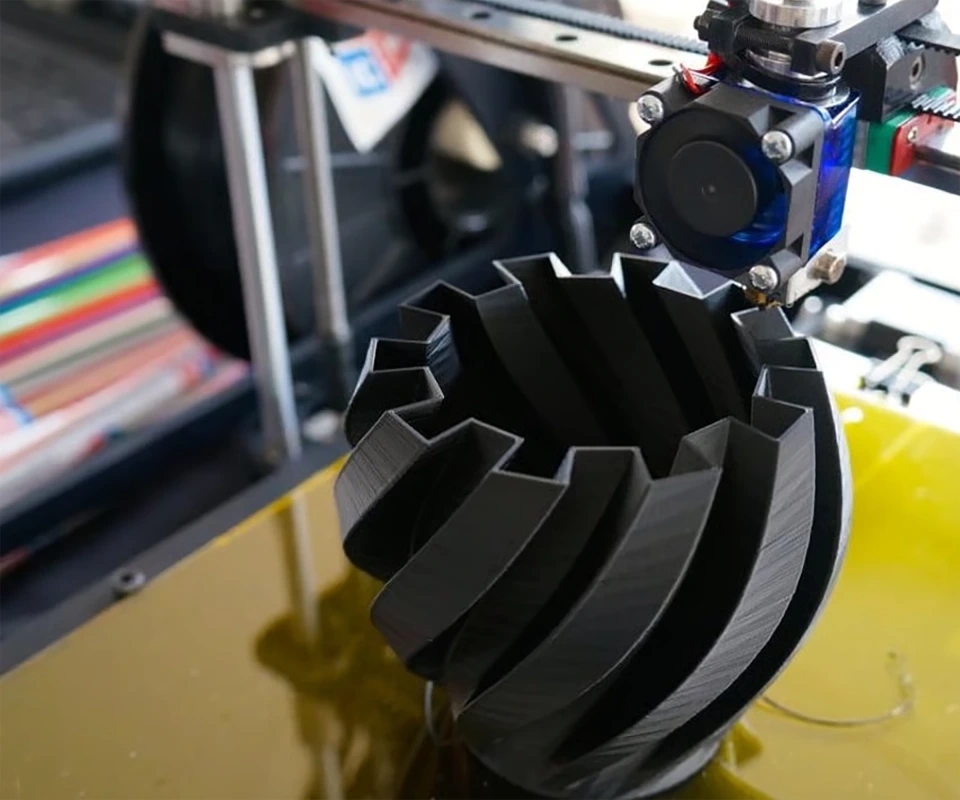

FDM (Fused Deposition Modeling) is the most widely used 3D printing technology. By heating the thermoplastic materials (such as PLA, ABS, nylon, etc.) to a molten state, they are then layer-by-layer deposited by the nozzle for forming. Its core advantage lies in:

Wide range of material options: Supports engineering plastics (PC), elastomers (TPU), and composite fiber materials (carbon fiber reinforced);

Low cost and high efficiency: The prices of equipment and consumables are affordable, making them suitable for rapid prototyping and small-scale production.

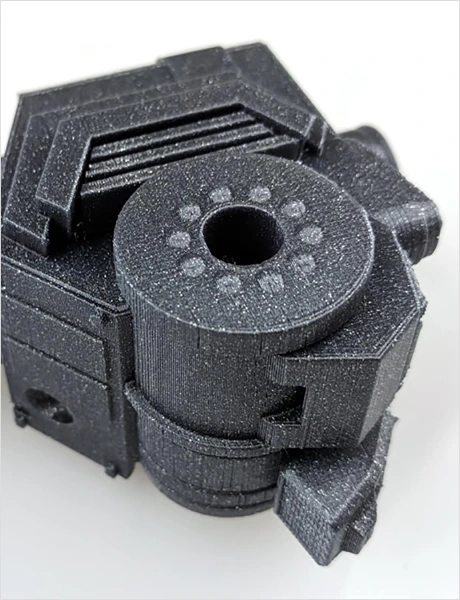

High functionality: Capable of manufacturing terminal components that are resistant to high temperatures (120℃+) and have impact resistance;

Low cost and high efficiency

By using engineering plastics such as PLA and ABS, the material cost is only one third of that of traditional processing. The prototype can be completed in as fast as 4 hours.

High-performance

Supports high-strength materials such as nylon and PC, with a temperature resistance of up to 120℃, meeting industrial-grade testing requirements.

High design flexibility

Easily achieve complex cavities and lightweight structures, without the need for mold investment.

Operation is simple

This desktop-level device can be used directly without any setup, suitable for factory, laboratory, and even home environments.

FDM (Fused Deposition Modeling) creates parts by layer-by-layer depositing molten plastic. The main process consists of three steps:

Features: Environmentally friendly, biodegradable, easy to print, low shrinkage Strength: Medium (tensile strength ~ 60 MPa) Temperature resistance: ≤ 50℃ (not resistant to high temperatures)

To start, simply select a manufacturing process and upload a 3D CAD file.

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Once you review your quote and place your order, we'll start the manufacturing process. We also offer finishing options.

Our digital manufacturing process allows us to produce parts in as fast as 1 day.