Our Surface Finishing Capabilities

Use Qiying as your one-stop solution for both manufacturing and surface finishing of your custom parts, reducing the risk of production. Here is a list of standard surface finishes. For custom surface finishes such as laser cutting or hard anodizing, please contact: infoqyprototypes.com

POLISHING

Polishing - The exquisite finishing process that gives materials an ultra-smooth surface

A manufacturing method that removes the microscopic irregularities on the material's surface through mechanical friction or chemical action, resulting in a smooth, highly glossy or special textured finish.

Enhanced finish: Surface roughness can reach Ra 0.01μm (mirror finish level)

Enhanced functionality: Reduces friction resistance, improves sealing performance, and enhances corrosion resistance

Aesthetic value: Customizable visual effects such as metallic luster / matte or frosted finish

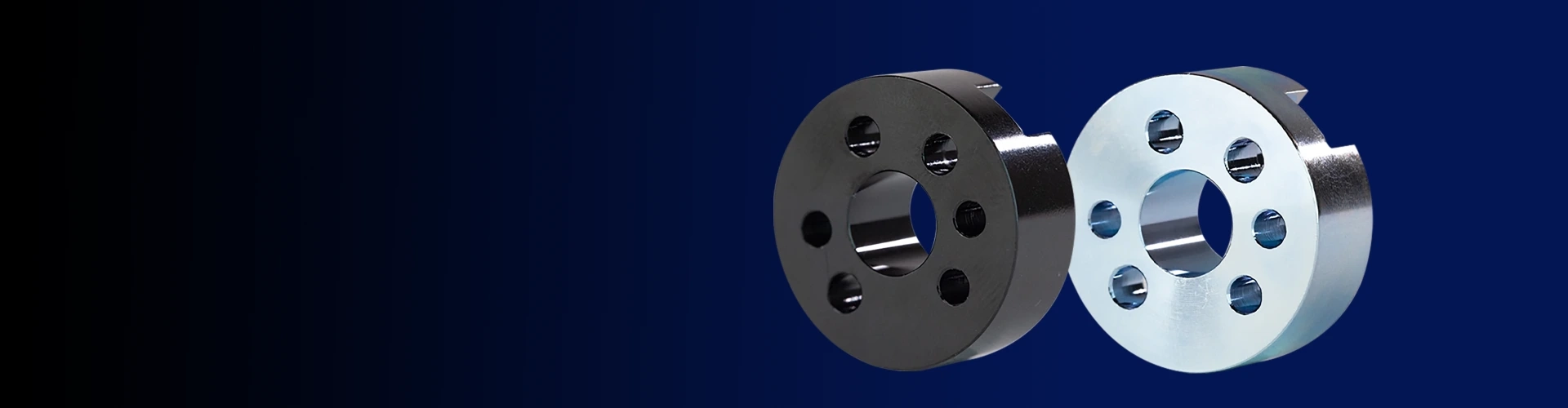

ANODIZING

Anodizing - An electrochemical process used to enhance the surface of metals

Anodizing is a process that forms a dense oxide film on the surface of metals such as aluminum, titanium, and magnesium through an electrolytic reaction:

High hardness: The hardness of the oxide film can reach HV300-500, significantly enhancing the surface wear resistance.

Corrosion resistance: After sealing treatment, it can withstand salt spray tests for 500-1000 hours.

Insulation performance: The resistance of the oxide film reaches 10⁹ - 10¹² Ω·cm.

Decorativeness: Electrolytic coloring can be used to obtain 20+ standard color schemes.

Adhesion: The oxide film is metallurgically bonded to the substrate and never peels off.

SAND BLASTING

Sand Blasting - The "beauty polishing technology" for metal surface treatment

A physical processing technique that achieves cleaning, roughening or matte finish effects by subjecting the metal surface to high-speed impact with abrasive materials (such as quartz sand/glass beads/steel balls, etc.).

Remove contaminants: It can remove the oxide layer, oil stains, rust, old coatings, etc. from the surface.

Efficient Handling: Suitable for complex shapes or inaccessible areas (such as crevices, grooves)

Enhanced Adhesion: By creating micro-roughness structures, it enhances the adhesion of coatings (such as paint, coating).

Uniformity: Capable of controlling the roughness (such as at the Sa2.5 standard), suitable for subsequent process requirements.

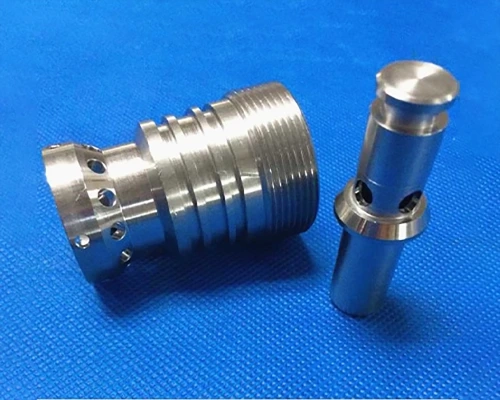

ELECTROLYTIC POLISHING

Electrolytic Polishing - A process that precisely polishes the surface of metals using electrochemical methods.

Electrolytic polishing is a technique that removes microscopic protrusions on the metal surface through electrochemical dissolution, resulting in an extremely smooth surface

Microscopic leveling: By selectively dissolving the raised parts on the surface, the roughness is reduced (reaching Ra 0.1 μm or below), achieving a mirror-like effect.

Luster enhancement: Eliminating mechanical processing marks (such as scratches, burrs), enhancing the reflectivity of the metal.

GALVANIZING

Galvanizing - The Classic Process for Preventing Metal Corrosion

Galvanizing is a technique that involves covering the surface of steel with a zinc layer (5-150 μm) to prevent exposure to corrosive media.

Excellent anti-corrosion performance, sustainability

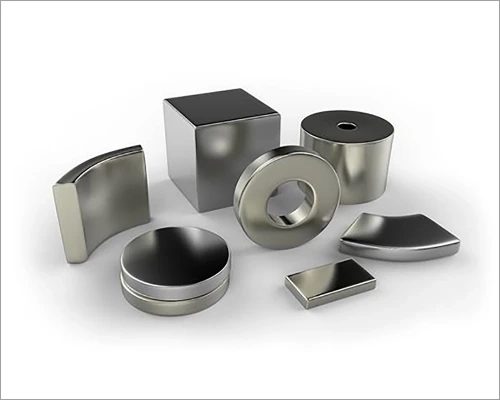

NICKEL PLATING

Nickel Plating - An electroplating process for enhancing the functionality of metal surfaces

Electroplating nickel is a technique that deposits a nickel layer on the surface of a metal (or non-metal) through electrolysis or chemical methods.

Corrosion resistance,Abrasion resistance,Good electrical conductivity,Easy to weld Resistant to high temperatures

PASSIVATION

Passivation - Chemical enhancement technology for metal corrosion prevention

Passivation is a process that forms a dense oxide film on the metal surface through chemical or electrochemical methods to enhance corrosion resistance.

Chemical stability: The passivation film is not easily dissolved in most acids, bases, and salt solutions.

Density:The film layer is extremely thin (at the nanometer level) and has no pores, effectively preventing corrosive media from penetrating.

Self-repairing property:After local damage, a new passivation film can be re-formed under oxidative conditions.

POWDER COATING

Powder Coating - An Environmentally Friendly and Highly Efficient Surface Coating Technology

Powder coating is a technology that uses electrostatic adsorption to spray solid powder onto the surface of a metal, and then undergoes high-temperature curing (typically at 180-200°C) to form a dense coating.

Environmental friendliness, economy, insulation, wear resistance, impact resistance

PAINTING

Post-processing (painting) - The elevated stage of artistic creation

"Post-processing (Spray Painting) — The Sublimation Stage of Artistic Creation""Spray painting is a surface treatment technology that uses spraying equipment to evenly coat (oil-based/water-based) paint onto workpiece surfaces, forming protective or decorative layers. It is widely applied to materials such as plastics, metals, and wood."

Post-processing (painting) - The elevated stagHigh Decorative QualityAchieves diverse visual effects including mirror gloss, matte finishes, metallic textures, and gradient colors.

Superior Protective PerformanceForms a dense coating resistant to corrosion, UV rays, and scratches (salt spray testing exceeds 500 hours).

Wide Material CompatibilityApplicable to various substrates such as plastics (ABS/PC/PP), metals, and fiberglass.